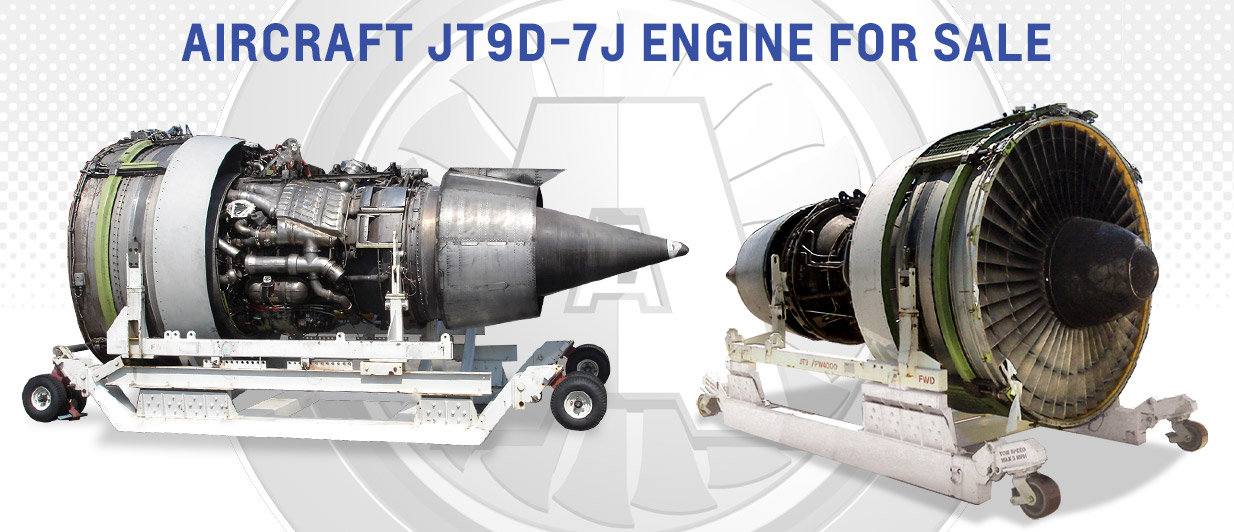

ENGINE FOR SALE

JT9D-7J Aircraft Engine

Product Specs

-

ESN :685969

-

TT :77,647

-

TC :19,684

-

TSR :0

-

CSR :0

-

MIN LLP :2,216 Cycles (C6 Disk)

-

MIN LLP :12,006 Hours (T2 Disk)

-

TEST CELL :9 degrees EGT

-

CONDITION :Fully Servisable with FAA 8130

-

TAG :Kallitta Maintenance 12/07/2013

-

BOROSCOPE :Clean within limits

-

NOTE :OHC fuel nozzles, combustion liners

-

Full B747 QEC

-

SHIPPING STAND :Included

-

Stage III noise certification

PDF Documents

Benefits of the JT9D-7J Engine

The JT9D-7J engine, as used on the Boeing 747-200 aircraft, offers several benefits. Here are some of the advantages associated with the JT9D-7J engine:

High Thrust

The JT9D-7J engine is capable of producing a significant amount of thrust, enabling the Boeing 747-200 to operate efficiently even at heavy loads and long-range flights. This high thrust capability allows for takeoff and climb performance, enabling the aircraft to reach cruising altitude swiftly.

Fuel Efficiency

The engine’s high-bypass ratio contributes to improved fuel efficiency. By bypassing a large portion of the incoming air around the engine core, the JT9D-7J achieves a more favorable ratio of bypass air to combustion air. This results in reduced fuel consumption and lower operating costs for airlines.

Low Noise

The high-bypass design of the JT9D-7J engine reduces noise levels compared to earlier engine models. The larger fan and bypass duct help muffle the noise generated by the engine, resulting in a quieter aircraft. This reduced noise level is beneficial for both passengers and communities surrounding airports, as it minimizes noise pollution.

Reliability

The JT9D-7J engine has a reputation for reliability. It underwent extensive testing and refinement to ensure its performance and durability. This reliability is crucial for long-haul flights, where the engine needs to operate consistently and safely over extended periods.

Proven Track Record

The JT9D family of engines, including the JT9D-7J, has a long and successful history of service on the Boeing 747-200 and other aircraft models. This extensive operational experience provides airlines and operators with confidence in the engine’s performance, maintenance, and support.

Serviceability

The JT9D-7J engine benefits from well-established maintenance practices and a global support network. This makes it easier for airlines to access spare parts, technical assistance, and maintenance services, ensuring minimal downtime and efficient operations.

Overview

The JT9D engine is a high-bypass turbofan aircraft engine manufactured by Pratt & Whitney. It was first introduced in the late 1960s and was widely used on several commercial airliners, including the Boeing 747, McDonnell Douglas DC-10, and Boeing 767.

The development of the JT9D engine began in the early 1960s as a response to the demand for more powerful and fuel-efficient engines for wide-body aircraft. The engine features a two-spool design, with a low-pressure compressor and high-pressure compressor driven by separate turbines. This design allows for better efficiency and improved performance.

Over the years, various models of the JT9D engine were developed, each with different thrust ratings and improvements. These engines underwent several upgrades and advancements to enhance their reliability, fuel efficiency, and overall performance. The engine series played a significant role in the development of long-haul air travel, enabling airlines to operate larger aircraft on intercontinental routes.

Post-Test Borescope Video (JT9D-7J) – ESN 685969